100

%

Leave a request

A manager will contact you soon

By clicking on the button, you consent to the processing of personal data and agree to the privacy policy

The company "Leto Group"

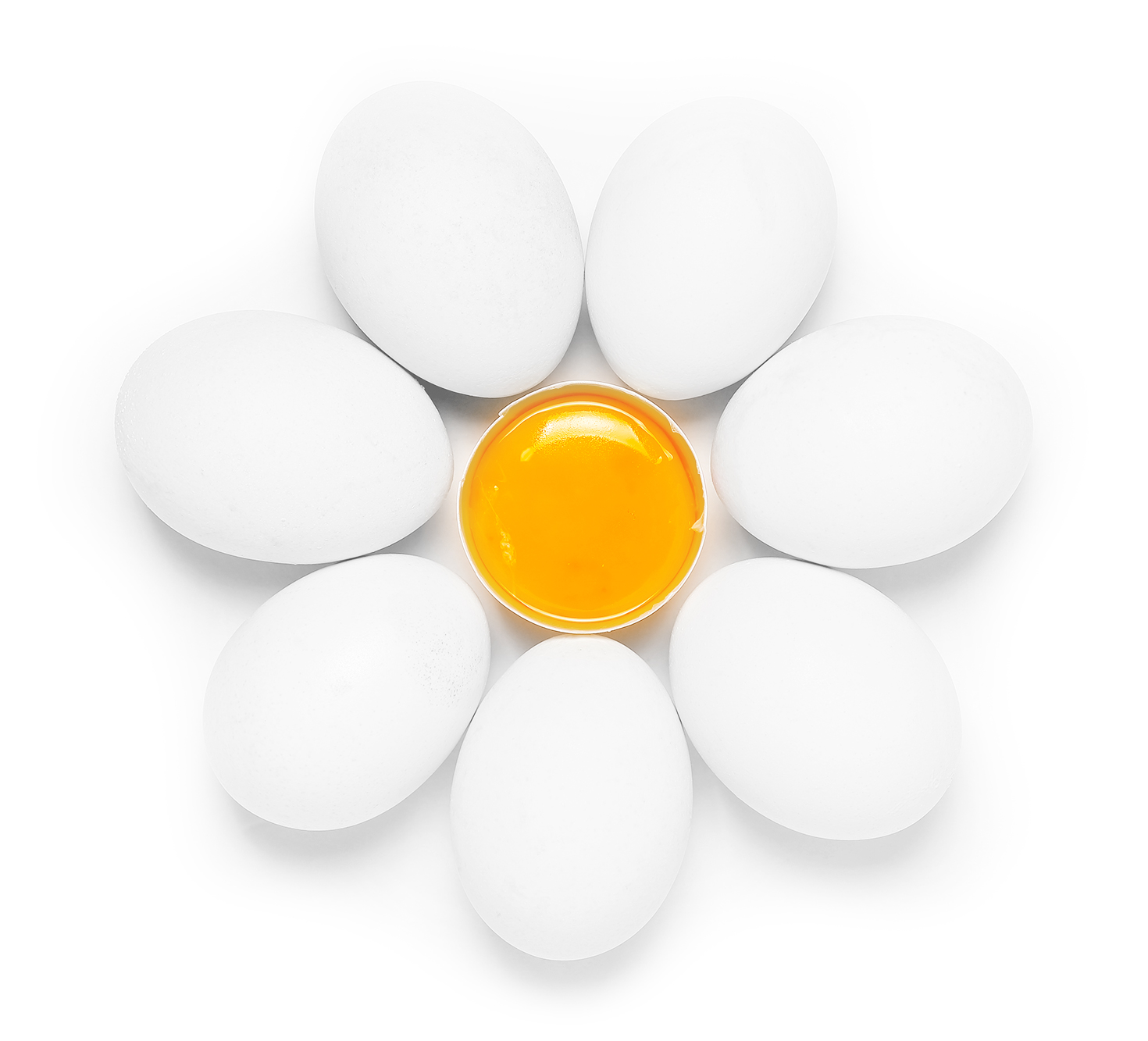

It is a modern and technological egg processing production, which holds a leading position among egg products producers. Advanced equipment of the Danish company SANOVO makes the company the most high-tech in Russia in the field of processing of edible chicken eggs.

- One of the leading egg processing enterprises occupying 25% of the Russian egg products market, integrating eco-friendly breeding hens, processing egg products and compliance with the entire production chain.

- Main products: dried and liquid egg yolk, dried and liquid egg white (albumen), dried and liquid egg melange.

- Passed the following food safety and quality certification systems: FSSC22000, IS022000, Halal and Orthodox Union.

- The leading agricultural enterprise in Tula region, which located in the Central Federal Region of the Russian Federation.

- Fully automated production with the ability to automatically determine the main characteristics of raw materials. The process of modernizing the production line and increasing the volume of products is still following on.

0

9

8

7

6

5

4

3

2

9

8

7

6

5

4

3

2

9

8

7

6

5

4

3

2

1

0

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

8

7

6

5

4

3

2

1

0

Eggs per day

- More than 4 billion rubles

Training course price - 18 000

sq.m.

Workshops during the course

10.2021

Plant launched in October 2021 having a rich history and the greatest experience

110 km

Production is located 110 km from Moscow

20 km²

The sanitary zone of the group of companies is 20 km²

120 members

120 members of staff, including administration and commercial staff

is to produce quality and safe products with impeccable consistency of performance.

We guarantee:

We guarantee:

The company's mission

Our employees

Professional development within the group of companies

Our suppliers

Long-term and profitable contracts

Our customers

Reliable production process and result

Quality control

R&D department

Equipment

Custom products

Naturalness

Prolonged storage

Certificates

In-house Research & Development department

Flagship technological lines of the European manufacturer

We produce specialized products according to customer specifications

Production without preservatives and anti-caking agents

Liquid products are stored up to 18 months after blast chilling and wave pasteurization

Quality stability is confirmed by FSSC22000

Availability of microbiological and physicochemical laboratories

© The company "Leto Group" 2023

01017, Tula region, Zaoksky district, Sosnovy village, p. 1

PSRN: 5137746102742

TIN / KPP: 7703801078 / 712601001

Privacy policy

01017, Tula region, Zaoksky district, Sosnovy village, p. 1

PSRN: 5137746102742

TIN / KPP: 7703801078 / 712601001

Privacy policy